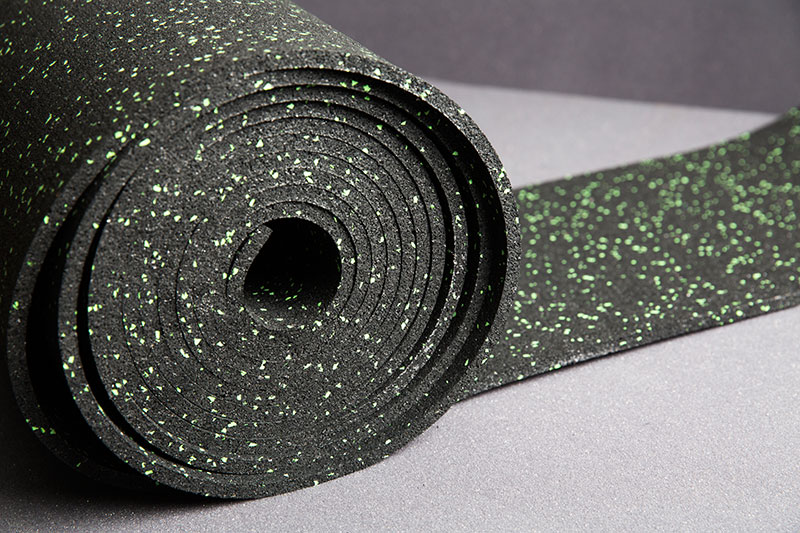

Anti-Slippage Mats

- Increased stationary and glide resistance

- Reduction of required lashing tension

- Reduction of the necessary lashing material

- Increased ratchet and lashing service life

- Environmentally-friendly recyclable material

STOBITEX Anti-Slippage Mats increase the resistance between loading surface and load. The mats are made out of a PU-bound rubber granulate (recycled material). Standard measurements are 5000 x 250 x 8 mm. The STOBITEX Anti-Slippage Mats are laid down before a load is placed onto the often otherwise slippery loading surface. They can easily be cut to the required size with a sharp knife.

Resistance is the friction created by the load against the loading surface. We differentiate between so-called stationary resistance and motion resistance. Stationary resistance is far more powerful than motion resistance. To illustrate this think of a heavy cardboard box, which you want to slide along the floor. The initial effort required to get it moving is large due to the stationary resistance. Once it is moving (motion resistance) the effort required in order to keep it moving is markedly less. Motion resistance is thus more relevant to load security.

The friction factor µ is applied to quantify friction levels. Without the mats, the factor observed during industry tests is 0.2. The friction force F is equal to the weight force G multiplied by the factor µ.

Thus F = µ x G. This means that an object weighing 100kg can be pushed by a force equal to 200 N or 20 kg along a clean flat surface. The mat simply raises the level of the factor, meaning that a greater force is needed to push the object. The lashing force required is reduced in this way i.e. using the same lashing force, force F (the force which is required to slide the load) is higher with anti-slippage mats than without.

The load is therefore more secure.