PU Spray Coatings

- Increased uses for webbing lifting belts

- Protection of the material against abrasive damages

- Extension of service life

- High flexibility of coated webbing

Download

- STOBIPREG-PU-Spray-Coatings (126.5 KiB)

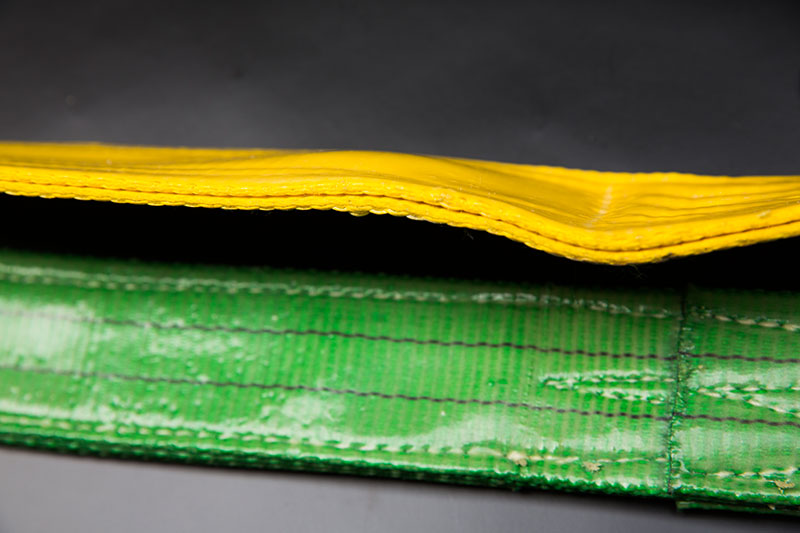

STOBIPREG PU Spray Coatings can be used wherever cut resistance is less important than protection of the material against abrasion and moisture. In this case one is also dealing with a PU Elastomer as used in the production of protective sheaths and the coating of belts.

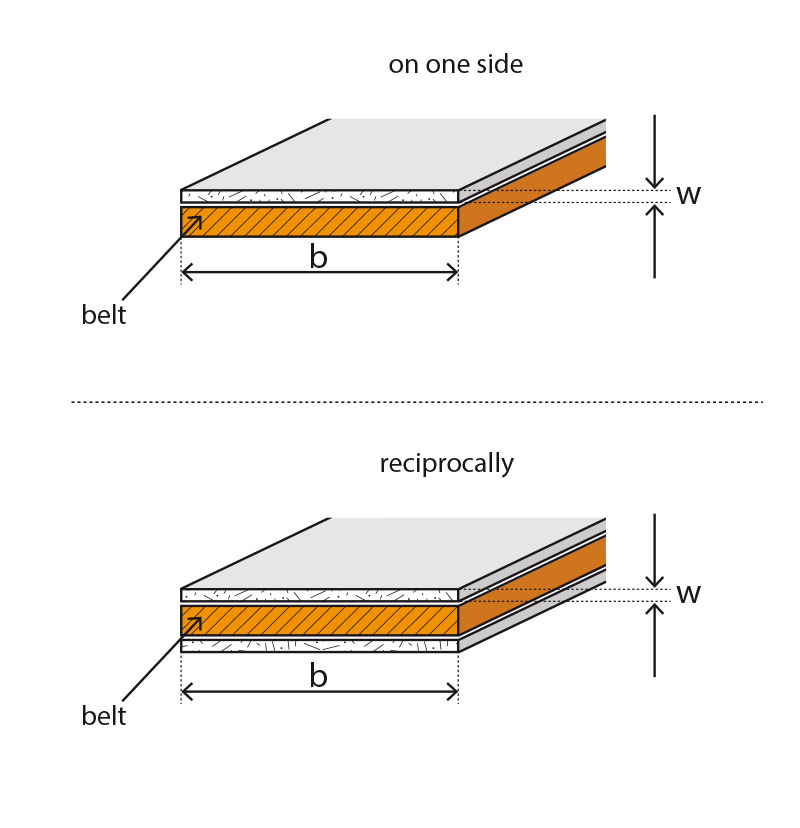

Advantage: excellent flexibility whilst offering good protection against abrasion. The coating thickness "w" is 0.5 - 1mm.

Typical uses are the lifting of rough objects (such as concrete pipes, marble blocks, and light plate steel loads etc.) or the use of the belts in road construction (abrasion and moisture protection).

STOBIPREG PU Spray Coatings can applied single or double-sided. Coatings can be applied to both finished belts and webbing rolls (rolls: discontinual manufacturing, maximum roll length 50m), which is only sewn to make belts once the coating process is complete.

The application of STOBIPREG PU Spray Coatings is carried out by a hydraulic airless high pressure PU machine. The extraordinarily high pressures used guarantee an excellent material mix and thus an outstanding end product.

Note: this form of coating exclusively serves as mechanical protection for the material against abrasion and moisture. The spray coating is not sealed and is not waterproof as such. If the material is to be protected against fluids (acid or alkaline solutions) then the use of our double-sided Stobitex PU-Coatings would be advisable

Material: PU Elastomer ca. 75-80 Shore A, colour transparent - opaque. Layer thickness 0.5 - 1mm.